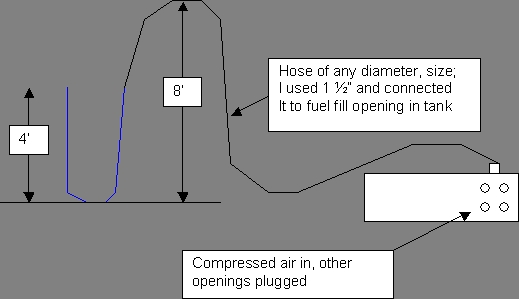

1. Because I was using non-clear hose, I arranged my hose as dimensioned in Figure 1. I poured water into the open end until it was even with the top so that I would have 48" of water in the hose, rising on each side of the "U". In the sketch this is denoted by blue.

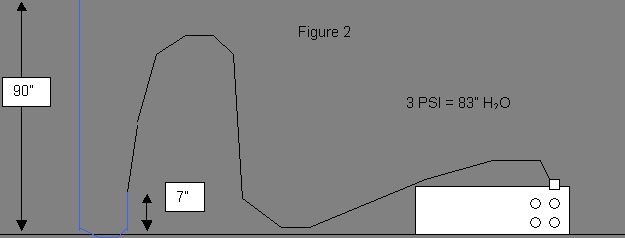

2. I then lifted the open end of the hose to 90" above the bottom of the loop. The 3 PSI I was shooting for corresponds to 83" of water column. That's 83" difference in the levels on each side of the "U". When pressurized the side of the "U" closest to the tank will be depressed down 41 ½" (83" divided by 2), the open end will be pushed up to 90" (48" of water at 0 pressure + the 83" divided by 2).

3. Attach air compressor, put air in until water level reaches top of open end of hose, close valve between air compressor and tank (to seal it and prevent air from back bleeding thru compressor). The benefit of this system is that very small air leaks show up quickly. A 1" drop in water level corresponds to a .06 PSI drop in air pressure. In my case a pinhole leak not detectable with a mixture of soapy water was finally found because I knew my water level was dropping. I finally found it when I notice a small amount of fuel oil on my empty, freshly primered tank.

FIGURE 1.